Electrostatic Guns

Wagner’s electrostatic atomisation process delivers a highly economical coating system, offering many advantages over conventional application techniques, in numerous areas of industry.

- Lower paint consumption

- Enormous time savings

- High surface quality

- Reduction in waste disposal costs

- Higher performance

- Innovative technology for any application

you might also like

FAQS

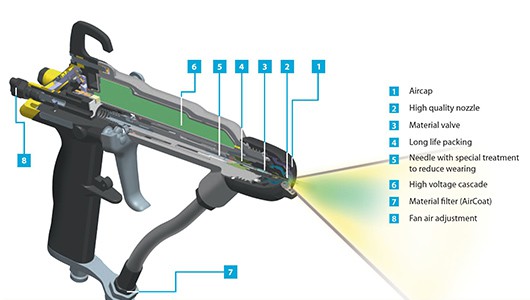

How does it work?

An electrostatic field is generated between the electrode in the gun head and the grounded work object. The paint particles are charged and attracted by the grounded object. This effect increases the efficiency significantly compared to non-electrostative systems. The “wrap-around” effect allows the operator to paint items such as pipes or hand rails without changing position.

What is the Multi-Swirl System?

Wagner has developed a unique multi-swirl system. As paint passes through the nozzle it starts a swirling motion. This produces a soft spray pattern with an increased “wrap-around” effect.

What are the typical applications of electrostatic spraying systems?

- Metal protection & finishing

- Wood finishing

- Plastic finishing

- Aerospace industry

- Automotive components

- Motorcycle parts

What fluids can be sprayed?

- Solvent and water based materials

- 1K & 2K paint

- Primer and top coat

- Low/medium/high solid material

- Paints and release agents

- PU and epoxy material

- Metallic paint

- UV paint

What are the benefits of electrostatic spraying systems?

- Lower paint consumption

- Enormous time savings

- High surface quality

- Reduction in waste disposal costs

- Higher performance

- Innovative technology for any application

AUD

AUD  NZD

NZD